Creativity Under Constraint with SXD

A Zero Waste Design-Tech Startup

Image courtesy of Shelly Xu

By Shelly Xu, Founder of SXD

Our clothing, our second skin, is one of the biggest polluters on our planet.

The global apparel industry produces about 92 million tons of textile waste a year. (1) That is about one garbage truck’s worth of fabric waste getting landfilled or burned every second, according to a 2017 report by the Ellen MacArthur Foundation. (2) I have seen my own childhood playground in Asia turn into a textile dumpster. The apparel industry is also notorious for unethical labor practices, and in Bangladesh, one of the top clothing manufacturers on earth, climate change is estimated to displace one in every seven people by 2050, many of them seamstresses. (3)

From organic cotton to recycling, increasingly more brands are seeking sustainable and ethical solutions. However, today’s sustainable fashion is an unpopular compromise. Sustainable clothing often costs more but doesn’t look better. Which is why only an insignificant fraction of people are actually buying sustainable fashion for their closets. When our team at Shelly Xu Design (SXD) began exploring this problem, we surveyed over 2000 people, and we learned that today’s sustainable fashion too often felt like a costly replica of existing basics—an uninspiring guilt trip that doesn’t feel worth it.

No matter how sustainable a piece of clothing is, if it’s not bought, worn, and loved by the wearer, it’s simply more waste.

To drive scaled adoption in sustainable fashion is to shift human behaviors. Just like how Tesla attracts even the non-environmentalists with their well designed cars, design will be a powerful tool for building desire and shifting behaviors in the apparel industry.

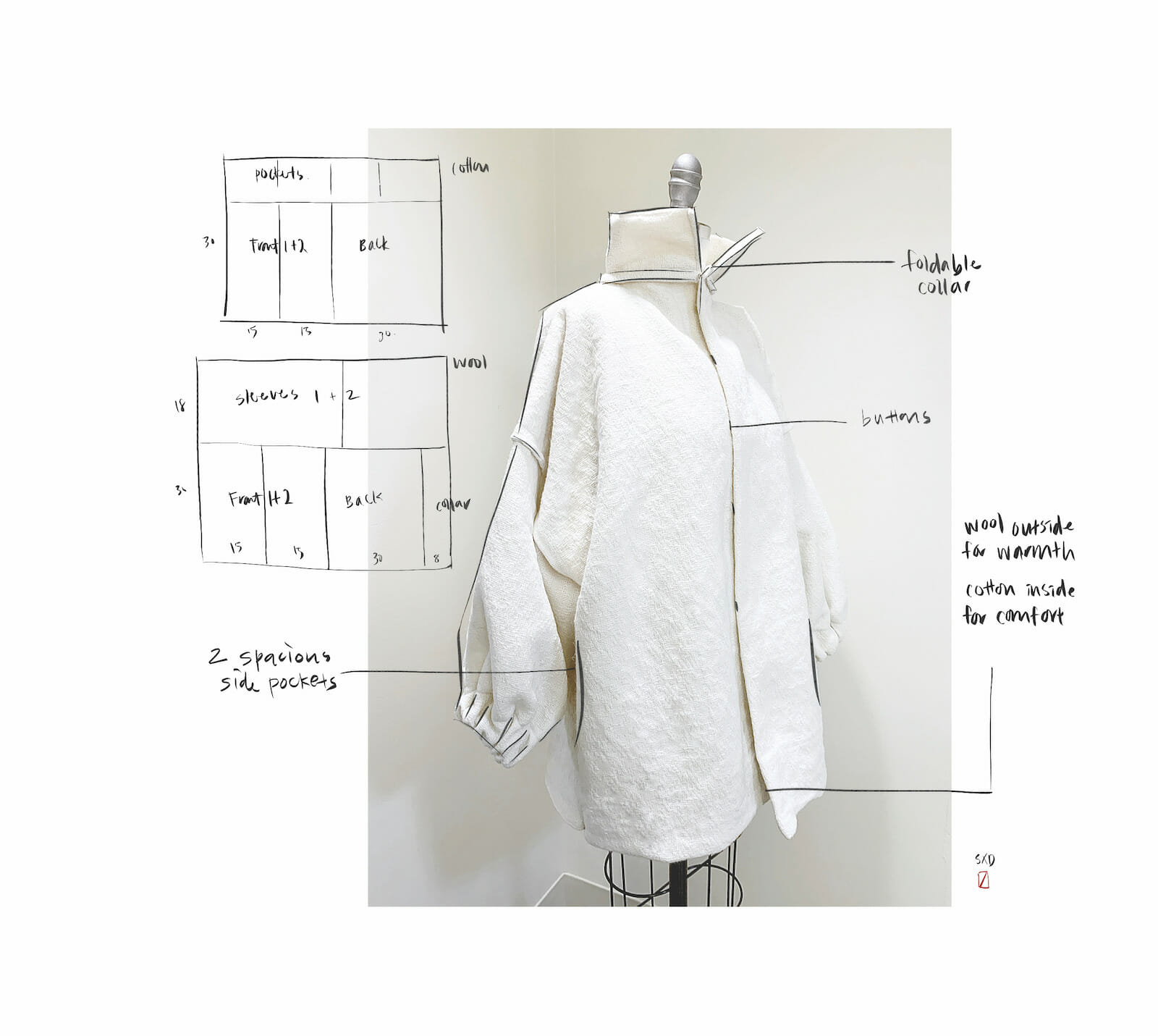

Image courtesy of Shelly Xu

Design Journey

My design journey began when I was just two years old. My earliest memory was sitting on a refrigerator while dining with my parents in a 70 sq ft home. We could only fit one table or one bed at a time, so we rearranged furniture to make daily life work. That was how I learned about creativity under constraints—discovering what’s possible with limited resources.

This concept fuels me and SXD’s zero waste designs. Today, fashion designs often start on a sketchbook or a drawing pad. The unconstrained artistic vision comes first. The fabric material is then cut to fit the shape of the vision. This process wastes 10-30% of the fabric and demands new fabric orders without addressing accumulated old fabric. On the other hand, SXD’s zero waste designs maximize desirability while acknowledging the limited resources on our planet, using leftover fabrics and not wasting anything, and designing within the boundaries of the existing fabric dimensions.

Image courtesy of Shelly Xu

Solution Building and Team Building

When I first began SXD, I tested desirability by starting an anonymous Instagram account and uploading zero waste design illustrations without actually revealing that the designs were zero waste. This allowed me to test whether or not people would find the product appealing even without the sustainability label. Shortly after opening this account, over 10,000 users began following the designs.

I then tested if the aesthetic was good enough to not only attract engagement but also conversion. I translated the most popular illustrations into real zero waste clothing, and sold them through Instagram for $300 each. I deliberately made the price high enough to ensure that the purchaser truly loved the design—it was not just a purchase out of kindness to support a new designer. At the same time, I also ensured that the price was low enough to still be accessible to many people, as the average US household spending on clothing is $1000-$2000 per year. When these zero waste clothing prototypes consistently sold out, I realized that we were getting closer to desirability.

Desirability in design is not only about creating aesthetic pieces, but also about creating accessibility and function.

Accessibility means designs that cost less rather than more to produce and scale. While many sustainable methods in fashion—from textile innovation to artisan work—add to the cost, zero waste designs have the potential to save cost by reducing fabric consumption. This can have a massive impact, as fabric is often the number one or two biggest cost that goes into apparel production.

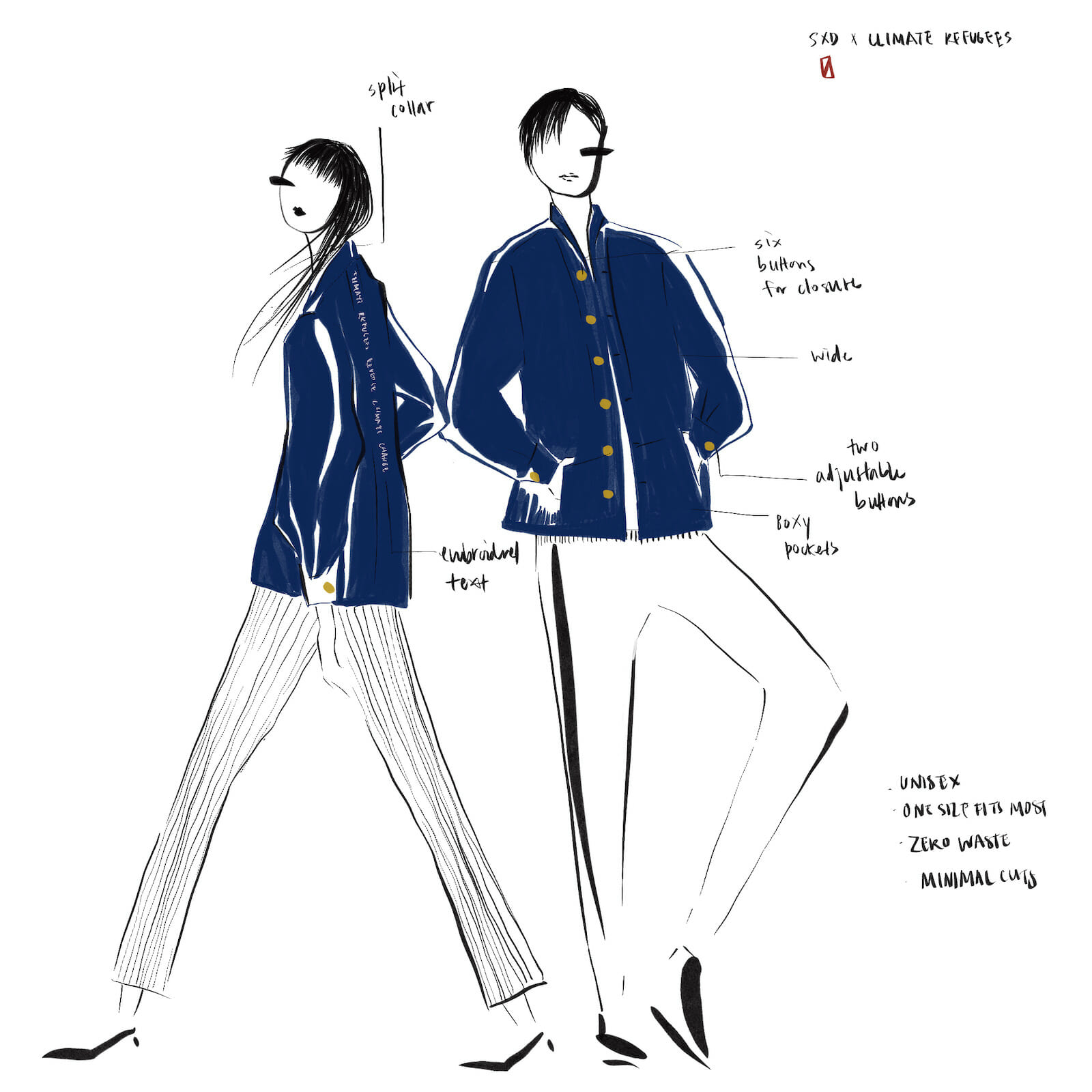

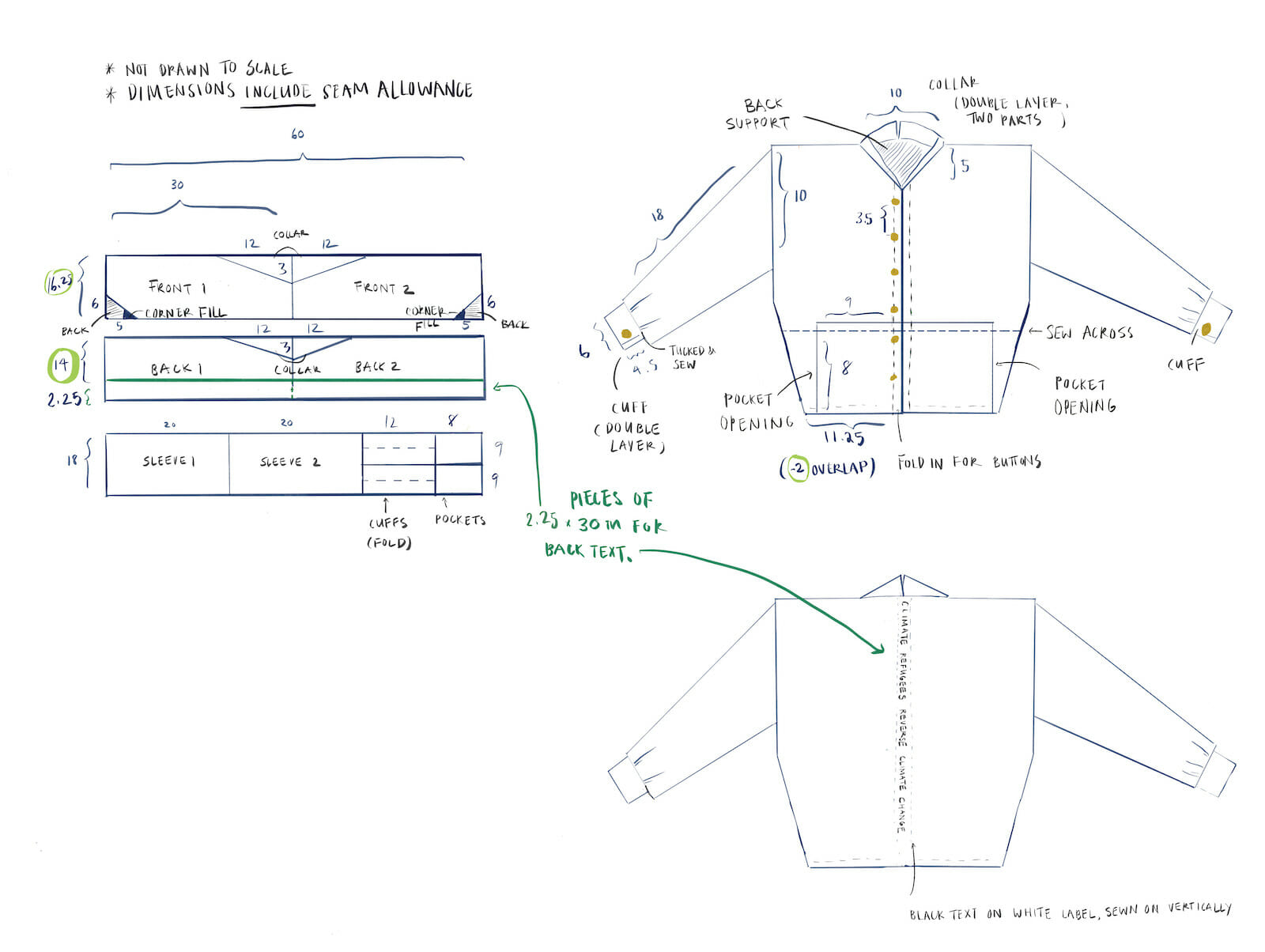

Image courtesy of Shelly Xu

Desirability in design is not only about creating aesthetic pieces, but also about creating accessibility and function.

Minimizing cost requires a combination of design and technology. Today, fashion designers are often far removed from engineers, so no creative designer is truly factoring in manufacturing efficiency. This is why sustainability efforts so far have been incremental rather than fundamental, and tend to add cost rather than subtract. For SXD, we built a team that combined design and engineering from step one, so our products are inherently efficient and easy to scale. We also deliberately design timeless garments with pockets that adapt to changing bodies. These versatile designs are more appealing to the modern customer who needs not only fashion but also function.

Combining design and engineering early on allowed our team to create highly efficient apparel that saves about 55% in production cost. We achieve this through minimal cuts, minimal fabric consumption, and zero fabric waste.

Photo by James Cheong

Photo by Joe Thomas

Developing our team also expanded my perspective around the ethics of apparel creation. Even before starting SXD, I already knew about unethical labor practices in the fashion industry, but I did not know the magnitude of it and how much unethical manufacturing practices and climate change are linked. Diving into the people behind the clothing taught me that the biggest manufacturing countries are also the worst hit by climate change. For example, in Bangladesh— one of the biggest clothing manufacturers in the world—textile waste is taking over, and by 2050, climate change will displace ~20 million people4 in the country. Understanding this pushed me to rethink my production model. I shifted SXD from a US-only to a global lens. I started learning more about climate refugees and onboarded Ahmed Fardin, a Bangladeshi engineer from Cambridge University who also researched zero waste design. Together, we began forming a network of climate refugees, paid them ~4x the local wage, and trained them to create zero waste clothing. We also worked with the nonprofit Youth Worldwide Foundation, which provides refugee skills training and hygiene support. As we incorporate automation to scale zero waste designs, we will be automating the most tedious parts for climate refugees rather than taking away jobs. This includes automating sampling, cutting and packaging. Understanding the refugees’ stories has also changed my design. I deliberately create minimal designs that are unisex, one-size-fits-all, and simple in cuts so that we can hire even the newly trained climate refugees.

Photos by Stephanie Cheong

Impact

So far, SXD’s prototypes alone have led to enough fabric “unwasted” to hang from a skyscraper’s 60th floor, over 240K liters of water saved (by upcycling rather than dying any fabric), and over 1 million interactions with our open source zero waste designs. Most of these interactions come from aspiring designers seeking a new way of creating clothing. We have also sold out prototypes with a growing waitlist, and have been invited to all major fashion weeks around the world.

But we are even more excited about the path ahead.

Just dropping products alone will not shift the multi-trillion dollar fashion industry. Once we have proven that we can produce solid zero waste designs that are sustainable, ethical and desirable, we will plug our work into other brands to broaden our influence. We are currently working on two partnership projects, turning best sellers of global apparel brands into zero waste clothing. We are also investing in technology that can automate zero waste designs to adapt to various brand styles at scale.

The apparel industry produces approximately 92 million tons of textile waste a year. Our mission is to make this number zero.

Photo by James Cheong

- https://www.bbc.com/future/article/20200710-why-clothes-are-so-hard-to-recycle

- https://www.ellenmacarthurfoundation.org/news/one-garbage-truck-of-textiles-wasted-every-second-report-creates-vision-for-change

- https://ejfoundation.org/reports/climate-displacement-in-bangladesh

- https://www.nrdc.org/onearth/bangladesh-country-underwater-culture-move